Investment casting is also known as the "lost-wax" process, is regarded as a precision casting process to fabricate near-net-shaped metal parts from almost any alloy.

The process begins with preparation of the wax patterns for every casting made. Wax is injected into an aluminum or steel die to produce a pattern that is an exact replica of the part to be produced. The patterns are clustered around a sprue. The cluster is dipped into a ceramic slurry made by suspending fine ceramic materials in silica-sol. The excess liquid is allowed to drain off from patterns, and then fine zircon sands are stuccoed on this ceramic coating. Thus a small shell is formed around the wax patterns. After drying, this process of dipping and stuccoing is repeated again and again, using progressively coarser grades of ceramic material, until a self-supporting shell has been formed. It takes approximately 5 to10 days to make the mould. When a shell thickness of approximately 6 to 10mm has been built, the molds are dewaxed by autoclaving (pressure and steam). This leaves a ceramic shell containing cavities of the casting shape desired with passages leading to them. The hollow shells are then preheated to 900-1200℃, depending on the alloy to be poured and the molten metal cast immediately into the hot shell. After cooling, the ceramic is vibrated and blasted off the metal parts and discarded. The balance of the cleaning operations (cut off, grind, heat treat, straightening, blast) are straight forward and quite similar to the other casting processes.

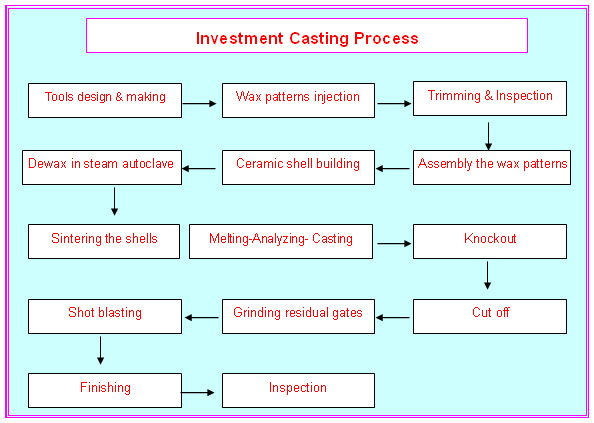

The process is show as the flow-diagram.

● ADVANTAGES OF INVESTMENT CASTING PROCESS

* With the ability to cast near net shapes, secondary machining can be reduced or completely eliminated. Material and machining cost can be reduced.

* The investment casting process has more design flexibility, can produce parts of various degrees of complexity. Previously fabricated assemblies can be cast as one part, so the production costs can be reduced.

* Wide choice of materials for wide applications, special materials also available on customer’s requirements.

* Lettering and Brand Logo can be cast on the castings to promote your company image.

* Superior repeatability and efficiency make mass production become easy.

● LIMITATIONS OF INVESTMENT CASTING PROCESS

* The process is normally limited by the size and mass of the casting. Usually, the mass of a investment casting is under 10kg.

* This is a more expensive process because of large manual labor involved in the preparation of the pattern and the mould. |